HS-IOT-CONNECT: Pioneering Industry 4.0 Connectivity

Successful Completion of HS-IOT-CONNECT Project: A Major Leap in High-speed IoT Connectivity

In July 2023, the HS-IOT-CONNECT project, a collaborative effort between Amorph Systems GmbH and the Fraunhofer Institute for Production Engineering and Automation (FhG-IPA), reached its successful completion. This project, funded under the Invest BW initiative by the Ministry of Economics, Labour, and Tourism in Baden-Württemberg, represents a significant leap forward in the domain of high-speed IoT (Internet of Things) connectivity.

From Start to Success

The voyage kicked off as Amorph Systems GmbH obtained endorsement for their innovative initiative from the state of Baden-Württemberg. Alongside a committed team from the Fraunhofer IPA, the objective was evident: to enhance and standardize near-instantaneous machine connectivity, transforming how industries use data for enhanced productivity and decision-making.

The Objective of the Project

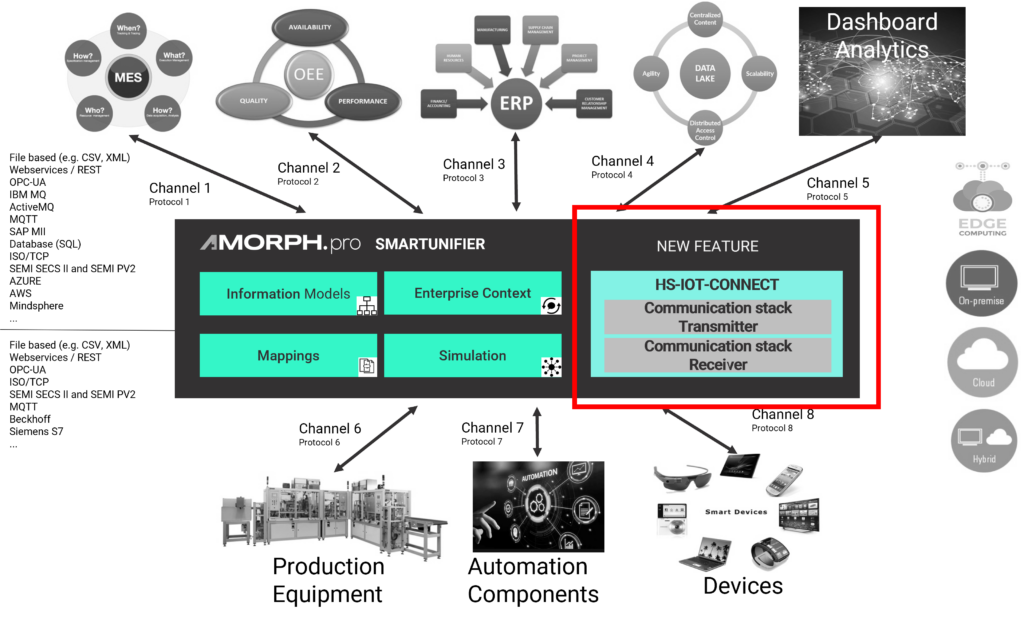

The HS-IOT-CONNECT project’s paramount objective was to deliver a flawless and high-speed connectivity answer. This would be realized through the development of a new feature, built to facilitate immediate data collection and transmission of a comprehensive digital machine representation – a term that the industry knows as the “digital system twin.” The distinctive feature of this venture was its dedication to using affordable regular network technology for this aim.

The Strength of Near-Realtime Connectivity

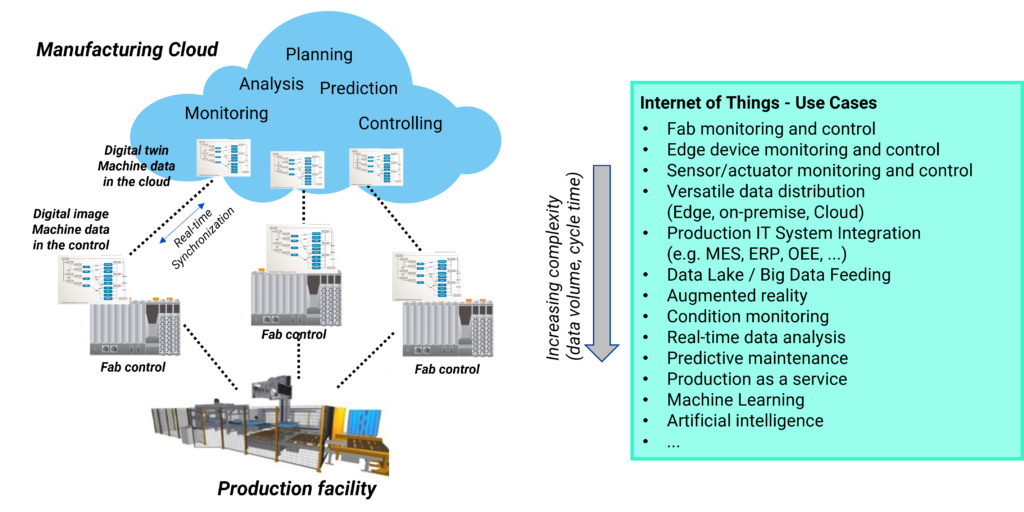

The project’s distinguishing characteristic was its capacity to convey a continuously changing digital machine model to superior cloud infrastructure in near-real-time, i.e. at very high speed with combined minimum latency. Contrary to conventional methods that require slow, tedious pre-filtering and preprocessing of data at the factory level, HS-IOT-CONNECT sought to transmit data from the origin directly from the equipment controller (Programmable Logic Device, PLC) to the cloud.

Harnessing the Power of the Cloud

The HS-IOT-CONNECT initiative’s most remarkable accomplishment was its ability to expand the reach of cloud-based applications to areas where near-instantaneous data processing is vital. The newly developed HS-IOT Communication Stack, which flawlessly merged with Amorph Systems’ SMARTUNIFIER, proved to be a fundamental facilitator for cutting-edge Industry 4.0 applications.

Industry 4.0 Transformation

The impact of HS-IOT-CONNECT is profound. It empowers industries to effortlessly implement a spectrum of advanced Industry 4.0 applications, including:

1. Condition Monitoring

Real-time monitoring of all system parameters and states becomes a reality, enabling early detection of issues and ensuring optimal performance.

2. Predictive Maintenance

With access to real-time data, predictive maintenance strategies can be efficiently deployed, reducing downtime and enhancing productivity.

3. Production as a Service

By streamlining data acquisition and transmission, the project facilitates the concept of “Production as a Service,” enabling agile and on-demand manufacturing solutions

Future-Shaping Innovations

The HS-IOT-CONNECT project’s core strength lies in its capability to dispense with the requirement for costly and complicated specific hardware. Instead, it employs commonly accessible standard network technology to achieve real-time data gathering and digital machine image transmission. This innovative approach not only streamlines processes but also promotes a cost and environmentally-friendly method of industrial operations.

Ecological Impact

HS-IOT-CONNECT provides a significant decrease in the demand for on-site service work from an environmental standpoint, as production facilities and procedures can be supervised and maintained remotely more than ever before. This enhancement also affects energy consumption, as detailed data scrutiny enables industries to reduce their ecological impact.

Practical Validation

The HS-IOT-CONNECT project surpassed theoretical development. Practical industrial use cases were carefully designed, tested, and authenticated at the Fraunhofer IPA. These use cases covered a wide range of scenarios including:

· Use Case – Quality Monitoring

In a sophisticated laboratory setting related to battery production, HS-IOT-CONNECT facilitated quality monitoring by accumulating high-frequency data from machines and nearby sensors. This information was flawlessly incorporated into the SMARTUNIFIER platform, providing real-time insights for proactive decision-making.

· Use Case – Condition Monitoring

In the realm of paper manufacturing and cutting facilities, the initiative enabled near-real-time condition monitoring of complex machine parameters like fast-changing pressures, currents, and voltages. By collecting high-frequency information in real-time, the system bolstered safety and efficiency, concurrently optimizing maintenance timelines for improved output of the production machines.

Concluding Remarks

The successful completion of the HS-IOT-CONNECT project attests to the strength of cooperation, innovation, and a continuous quest for Industry 4.0 superiority. It lays the groundwork for a future where near-real-time connectivity is standard, and different industries can use data to come up with high efficiency, sustainability, and flexibility. As the project wraps up, its long-term impact will persistently influence the progression of IoT connectivity and Industry 4.0.

Get our flyer NOW :