SPS 2025 Insights: Turning Connectivity Into Real Business Value

As SPS 2025 comes to a close, we look back on three inspiring days in Nuremberg filled with innovation, collaboration, and meaningful conversations about the future of industrial automation and IT/OT integration.

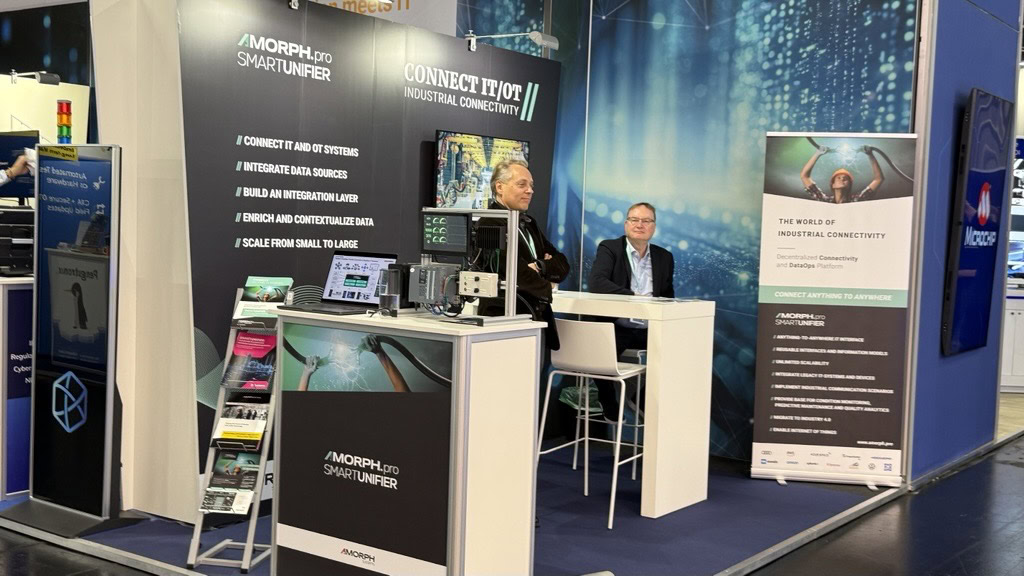

Once again, Amorph Systems took part in the “Automation meets IT” joint booth in Hall 6 (Booth 6-351A) — a perfect stage to demonstrate how our SMARTUNIFIER solution empowers manufacturers to achieve real-time, data-driven operations and unlock the full potential of Industry 4.0 and AI.

Powering Smart Manufacturing with SMARTUNIFIER

At this year’s SPS, we showcased how SMARTUNIFIER, our advanced industrial connectivity solution, bridges the gap between Operational Technology (OT) and Information Technology (IT) — securely, seamlessly, and in real time.

By enabling continuous data exchange across machines, systems, and enterprise applications, SMARTUNIFIER helps manufacturers achieve:

Up to 90% reduction in effort when handling customer complaints

– Accelerate root cause analysis with instantly contextualized production data

– Improve product quality through early anomaly detection

– Reduce time and costs in resolving customer issues

Up to 20% more efficient use of production equipment

– Real-time OEE insights for availability, performance, and quality

– Lower maintenance costs and longer system lifecycles

– Reliable, KPI-based decisions driven by live, accurate data

AI-ready production environments

– Seamless data collection and contextualization from diverse systems

– Clean, standardized data streams for predictive maintenance and smart planning

– A faster path from pilot projects to scalable AI deployment

Key Takeaways from SPS 2025

Throughout the event, one theme was clear: connectivity is the foundation for intelligent manufacturing.

Visitors to our booth discussed challenges and opportunities that are shaping the industry, including:

🔹 Secure and Scalable IT/OT Integration – Bridging diverse systems to enable real-time collaboration between production and enterprise layers.

🔹 AI and Data Readiness – Preparing manufacturing data for machine learning and predictive insights.

🔹 Operational Efficiency – Using contextualized data for faster decisions, reduced downtime, and improved quality.

🔹 Sustainability Through Digitalization – Leveraging data to minimize waste, energy use, and carbon footprint.

The very interesting discussions around these topics reaffirmed the growing importance of flexible, vendor-independent connectivity platforms like SMARTUNIFIER.

A good Place for Collaboration and Innovation

Beyond the technology, SPS 2025 was a get-together of people — partners, customers, and innovators who are shaping the future of manufacturing. We were inspired by the discussions at our booth, the enthusiasm for real-world AI applications, and the shared vision for a more connected, efficient, and sustainable industry.

We talked about the importance of manufacturing data in the assembly of tool machines, elevators, mechanical tools, and many more as well as possible partnerships with AI experts and industrial connectivity giants – not to forget research institutes and universities.

Looking Ahead

As we close another successful SPS, we’re more motivated than ever to improve industrial connectivity and AI-driven manufacturing.

If you want to learn more about how SMARTUNIFIER can help you reduce costs, enhance efficiency, and make your production AI-ready, visit amorph.pro or get in touch with our team.

Together, we’re shaping the future of smart manufacturing — one connection at a time.