MQTT vs OPC-UA: Comparing Industrial Connectivity Solution

“MQTT requires a centralized architecture”, says the CIO.

“OPC-UA over MQTT solves all issues we have with our shopfloor connectivity”, says the OT specialist.

“OPC-UA is good but too complicated”, says the internal software developer.

“MQTT 5 together with Sparkplug is the answer to all your questions”, says sales.

“Unified Namespace is only available for MQTT Brokers”, says another one.

These and other statements can be heard again and again. If you dig deeper into this, you will find that MQTT and OPC-UA are actually two different topics and that the comparison of them is not as simple as it seems to be. It is not a simple requirements list where you can make crosses and where one side wins.

Apple and Orange Architecture

Everything starts with a basic understanding of both topics.

What is MQTT?

The Message Queuing Telemetry Transport – or MQTT – messaging protocol uses the publish-subscribe pattern as its basic concept. MQTT’s publish-subscribe model requires a broker, which is the central point of communication. Clients can connect to this message broker and exchange data with each other via so-called topics, which are sent with every message. If a message is published on a specific topic, it is forwarded to all participants who have subscribed to it.

MQTT was originally developed by IBM for M2M communication in the Internet of Things (please note the missing word “Industrial”), in particular, to enable data transmission in locations with limited infrastructure networks and energy-saving devices with limited computing power. A few years ago, MQTT was officially defined as an OASIS standard. The latest (since 2019) specification is MQTT 5.

What is OPC-UA?

OPC-UA (Open Platform Communications – Unified Architecture) is a data exchange standard for industrial communication, providing platform-independent communication on various operating systems. OPC-UA is vital for Industry 4.0 and the Industrial Internet of Things (IIoT), enabling secure, real-time communication and extensive data modeling, semantics, and two-way communication.

The server/client architecture is the traditional communication model in OPC-UA. It is based on the idea that there is a server component that provides data for other applications that act as clients. Client applications can access data and information from the passive server via standardized services.

To briefly summarize: OPC-UA focuses more on data, data models, semantics, etc. whereas MQTT is more focused on the technology on transmitting data.

Comparing Apples with Oranges

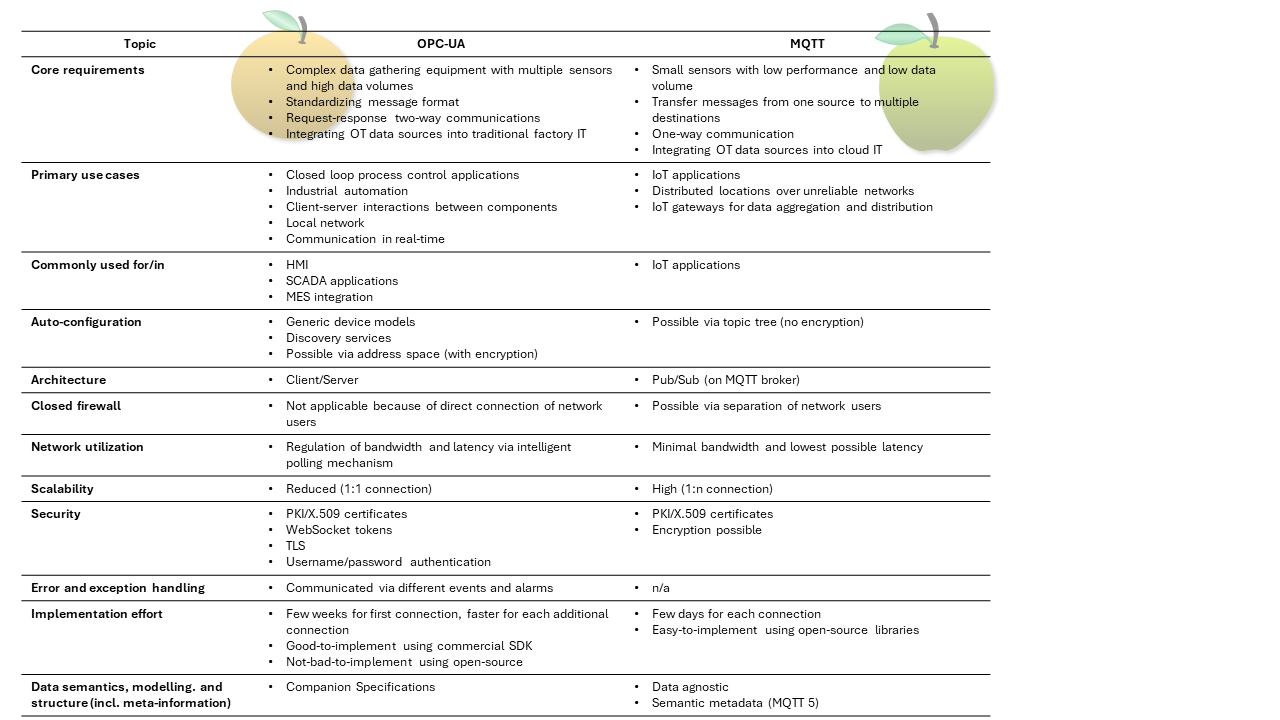

The following comparison makes the differences obvious.

OPC-UA was built for the purpose of gathering complex and/or high volume data coming from possibly multiple sensors within one equipment. Its focus on the content (data and commands/methods) means that it provides solutions for data modelling, semantics, meta data, and more. It is designed to support two-way communication not only for data collection but also for providing control data to the equipment such as recipes or equipment programs. It is the first choice when it comes to integrating OT data (sometimes called “South”) into the traditional factory IT (sometimes called “North”).

OPC-UA is able to support industrial automation and process control applications and direct M2M communication between components and also supports real-time communication. You will find OPC-UA devices and equipment in big SCADA environments as well as in a high number of shopfloor equipment and devices, less in small and low energy-consuming sensors.

Since OPC-UA is closer to the capabilities of the equipment itself it provides more information besides the data being collected. This information can be error and exception handling, which are communicated differently through events and alarms, completely separated from the payload.

MQTT is much more lightweight and is more representative of the hierarchy of the ISA95 pyramid. It was built to be used by small sensors with low performance and low data volume. It supports one-way communication and the main use case is to integrate OT data sources into cloud IT. It always comes with an MQTT message broker that orchestrates the publish and subscription partners.

Is MQTT more a protocol for consumer IoT devices? Yes, because devices such as “intelligent” power sockets are available, OPC-UA devices not so. No, because there are a lot of IIoT devices that support MQTT. MQTT scales much better than OPC-UA because of its architecture. We will come to this downside of OPC-UA respectively upside of MQTT later on.

So, coming from a dedicated use case it is in most cases not a question of using MQTT instead of OPC-UA or vice versa. The use case itself proposes the one, the other, or both solutions. SMARTUNIFIER makes the decision even easier.

Downsides and upsides of MQTT

Although MQTT is frequently used in industrial IoT infrastructures, the communication protocol is not standard in known control systems. This means that the necessary data must first be read out via other standards or protocols in order to afterward process it further with MQTT. SMARTUNIFIER with its capability of a protocol conversion and data mapping is the perfect unification building block for this purpose.

Furthermore, the message content – the payload – is not specified, which is why the corresponding message structure must be made known to the sender and receiver in advance. If this is not observed, the participants exchange the data but do not understand the message content. Well-known message structures that are often used are, for example, JSON or XML.

With this downside, Unified Namespace as a concept jumps in to provide support. Since SMARTUNIFIER also supports this concept, SMARTUNIFIER can be used to implement UNS.

One advantage of MQTT is the publish/subscribe architecture and communication via the MQTT broker. The decisive factor here is that the devices and applications are completely decoupled, as each client only knows the message broker, but not the other participants. In addition, the decoupling of the participants brings great added value to the separation between IT and OT, especially when it comes to security-relevant infrastructures.

MQTT enables 1:n communication, so it is possible for a single message to be published by a subscriber to a topic, but several subscribers can receive the message from the broker. Another popular feature of the communication protocol in connection with IoT use cases is the protocol features of MQTT. These features address typical issues in constrained infrastructures where bandwidth is compromised or connectivity is unstable.

Downsides and upsides of OPC-UA

OPC-UA is still not supported natively by many machines and systems in the field. For such systems, it is advisable to upgrade them with additional hardware using a retrofit approach or by using SMARTUNIFIER. This enables the data to be queried via existing protocols of the systems and machines, such as Modbus RTU and others. The data is then adapted and can be made available to other network participants and cloud systems in the form of an OPC-UA server. This means that old and new systems can be connected to each other without much effort and exchange data via an OPC-UA interface.

With its standardized communication, OPC-UA offers the possibility to share data not only on a vertical but also on a horizontal level. A standardized communication option between IT and OT is an essential approach for Industry 4.0, particularly with regard to vertical data exchange.

On a horizontal level, SMARTUNIFIER helps by acting as an OPC-UA server and therefore emulates an equipment to compensate the one or the other disadvantages.

From a vertical perspective, the possibility is created to provide data from lower layers (e.g. equipment) to higher levels such as MES or ERP. In addition, a combination of OPC-UA and MQTT makes it possible to forward recorded and pre-processed data directly to a cloud system such as Microsoft Azure or AWS. This provides the option of exchanging and using data at all levels of an existing company structure.

Unlike MQTT, OPC-UA communication partners are tightly coupled to each other. While this has its purpose and advantages, a decoupling might be a better solution for your specific data connectivity depending on the addressed use case. SMARTUNIFIER is able to decouple OPC-UA devices and act like an intermediary layer.

SMARTUNIFIER works as the harmonizer for MQTT and OPC-UA

SMARTUNIFIER is able to compensate the downsides of both technologies and provides additional functionalities and capabilities. To sum them up:

- MQTT does not have data semantics and models included. It even shows itself as data agnostic. SMARTUNIFIER helps to customize information models even using Unified Namespace ideas and concepts and harmonizes data models over equipment and business applications.

- OPC-UA is currently not available on small devices possibly important e.g. for a consistent energy management. SMARTUNIFIER is capable of converting MQTT protocols to OPC-UA as well as vice-versa and thus harmonizes the connectivity to SCADA and other applications.

- MQTT does not support native error handling or condition monitoring of connected equipment. SMARTUNIFIER may act like an OPC-UA device and add error handling and condition information based on customized algorithms. On the other hand, SMARTUNIFIER may act like an MQTT device and can wrap error messages coming from the device into the payload.

- OPC-UA is a client/server architecture with point-to-point connections. SMARTUNIFIER is able to provide 1:1 as well as 1:n communication and can therefore act as an intermediary layer even if it is based on a decentralized architecture. On the other hand, SMARTUNIFIER supports point-to-point connections to third-party message brokers.

- OPC-UA does not support the separation of networks between their components. SMARTUNIFIER may act as a hub or router between these components.

- OPC-UA is in many times too complex to be implemented by OT departments. Using SMARTUNIFIER makes it easy due to its low-code/no-code configuration.

- MQTT in its specification is a one-way communication. Two-way communication can be supported by complex customization of the MQTT Broker. SMARTUNIFIER is able to provide two-way communication.

Conclusion

Choosing between MQTT and OPC-UA depends on specific use cases. However, SMARTUNIFIER makes it easier by supporting both protocols, providing a future-proofing solution for your industrial connectivity needs. Embrace the revolution in industrial connectivity with SMARTUNIFIER, ensuring data integrity, seamless integration, and unmatched performance.

With SMARTUNIFIER it is just no question what technology or protocol you use. Use them both depending on what your devices support and unify them.

Smart Industrial Connectivity with SMARTUNIFIER: Performance, Security, and Easy Scaling

Unmatched Performance and Security: Engineered to excel in demanding industrial connectivity environments, SMARTUNIFIER delivers unparalleled data transfer speeds and robust security protocols. Trust in SMARTUNIFIER to ensure critical operations run smoothly while upholding data integrity.

Effortless Scalability: As your business expands, so do your industrial connectivity needs. SMARTUNIFIER effortlessly scales to accommodate growing data volumes and complex integration requirements, all without sacrificing efficiency or performance in industrial connectivity.

Intuitive Interface: Unlike many industrial solutions, SMARTUNIFIER features a user-friendly interface tailored for industrial connectivity. Empower your team with the ability to manage and monitor integrations seamlessly, reducing reliance on specialized IT personnel in industrial connectivity.

Why SMARTUNIFIER Stands Out in Industrial Connectivity

While competitors offer strong integration capabilities, SMARTUNIFIER‘s de-centralized architecture and user-centric design set it apart in industrial connectivity. Say goodbye to centralized bottlenecks—SMARTUNIFIER‘s distributed approach ensures continuous, high-speed data flow in industrial connectivity. Plus, its straightforward interface translates to faster implementation and reduced training times, giving your business a competitive edge in industrial connectivity.

Experience the Future of Industrial Connectivity with SMARTUNIFIER

SMARTUNIFIER isn’t just a data integration tool; it’s a revolutionary platform designed to support future-proof industrial operations and enhance industrial connectivity. Its blend of de-centralization, high performance, scalability, and ease of use makes it the ultimate choice for businesses seeking to elevate their industrial connectivity infrastructure. Embrace the future of industrial connectivity with SMARTUNIFIER and unlock unparalleled efficiency and reliability in your industrial processes. Transform your industrial connectivity with SMARTUNIFIER‘s advanced integration system, and experience seamless data integration, unmatched performance, and effortless scalability for your industrial operations.