Streamlining IIoT Platform Management Across Multiple Plants

In the realm of Industry 4.0, the integration of Internet of Things (IIoT) technologies has become indispensable for modern manufacturing plants. The basis for this is the introduction of an IIoT platform for seamless data integration that can be used uniformly across different plants. However, managing an IIoT platform across multiple plants presents a unique set of challenges.

From ensuring seamless communication to sharing crucial knowledge about information flows and transformation processes, an effective operations model is essential for optimal performance. In this article, we explore a suggested operations model for maintaining an IIoT platform across multiple plants and enabling knowledge and information sharing.

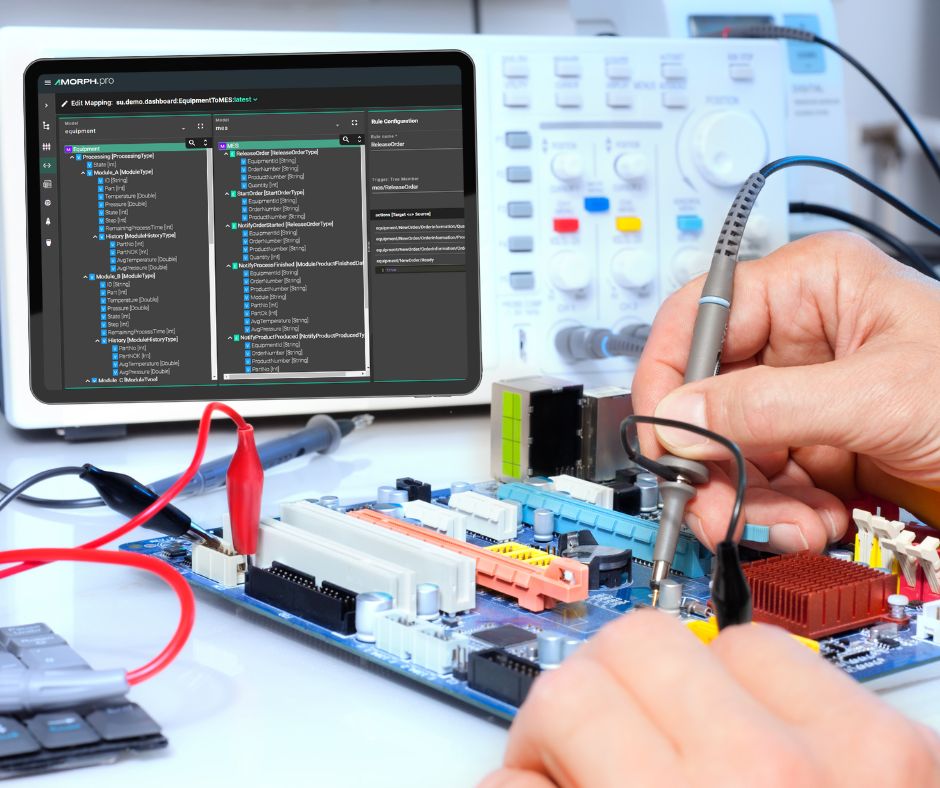

The suggested operations model revolves around the implementation of SMARTUNIFIER to serve the IIIoT platform requirements across several plants. In this context, SMARTUNIFIER Manager serves as the cornerstone for the configuration, deployment, and monitoring of all communication instances required within a specific plant for data connectivity. Alternatively, for scalability and efficiency, the SMARTUNIFIER Manager can operate within a Cloud Computing Center, serving multiple plants simultaneously.

Key components of this operations model include

1. Enterprise-wide Management with SMARTUNIFIER Manager: By installing SMARTUNIFIER Manager within each plant or operating one SMARTUNIFIER Manager within the Cloud, a comprehensive and enterprise-wide IIoT platform management is established for configuring, monitoring and controlling all decentralized IoT communication instances across the enterprise. This ensures streamlined configuration, deployment, and monitoring processes across all plants.

2. Test and Staging Environments: To mitigate risks associated with changes or updates, each plant is equipped with its own test and staging environment. These environments incorporate independent SMARTUNIFIER Managers, allowing for thorough testing before implementing changes in the production environment.

3. Versioned Artefacts: Information Models, Mappings, Channel configurations, and other artifacts are versioned and stored within the SMARTUNIFIER Manager’s repository. This ensures high reusability and facilitates efficient iterative refinement of interfaces.

4. Inter-Manager Configuration Exchange: SMARTUNIFIER Managers enable the seamless sharing of Information Models and Mappings across plants. By allowing interface configurations from one plant to be reused in another, they reduce setup times for new instances and promote global standardization of configurations and information models.

5. Empowering End Customers: With SMARTUNIFIER being a standardized tool, end customers can be trained to configure and operate it independently. This empowers customers to build up expertise within their facilities, leading to significant cost reductions through the presence of in-house experts.

Enhancing Efficiency and Collaboration in IIoT-Enabled Manufacturing Environments

By implementing this operations model, organizations can effectively manage an IIoT platform across multiple plants while enabling seamless knowledge sharing regarding standardized information models and flows. This approach not only enhances operational efficiency but also fosters collaboration and standardization across diverse manufacturing environments. As Industry 4.0 continues to evolve, leveraging advanced operations models becomes increasingly vital for staying ahead in the competitive landscape.

Staying Ahead in IoT and Industry 4.0: Continuous Improvement and Adaptation

In addition to the robust operations model outlined above, continuous improvement and adaptation are imperative in the dynamic landscape of IoT and Industry 4.0. Organizations must prioritize staying abreast of emerging technologies, evolving standards, and best practices to optimize their IIoT platform management effectively. By fostering a culture of innovation and collaboration, companies can further enhance their operational efficiencies and drive sustainable growth in the digital era.

Smart IIoT Platform Management Using SMARTUNIFIER Manager

Are you ready to streamline your IIoT platform management and advance your manufacturing operations to the next level? Embrace the suggested operations model outlined in this article and leverage the power of SMARTUNIFIER Manager to achieve unmatched efficiency and scalability. Get started today and embark on a journey towards enhanced productivity, agility, and competitiveness in the Industry 4.0 landscape.