Unify Data For Manufacturing Interoperability

How to unify data?

Data exists at all levels and in various forms within manufacturing enterprises. The challenge is to have a unified view of manufacturing data that will enable vertical and horizontal interoperability. Achieving this synergy between systems and components makes new levels of efficiency and quality possible.

Technological advances in shopfloor equipment and the Industrial Internet of Things (IIoT) have resulted in the availability of massive amounts of data. This data exists in different components and systems, in various formats, with separate access protocols. To harness this data’s power and benefit from the synergies of system-wide interoperability, we need a smart way to unify data.

The easy way to connectivity

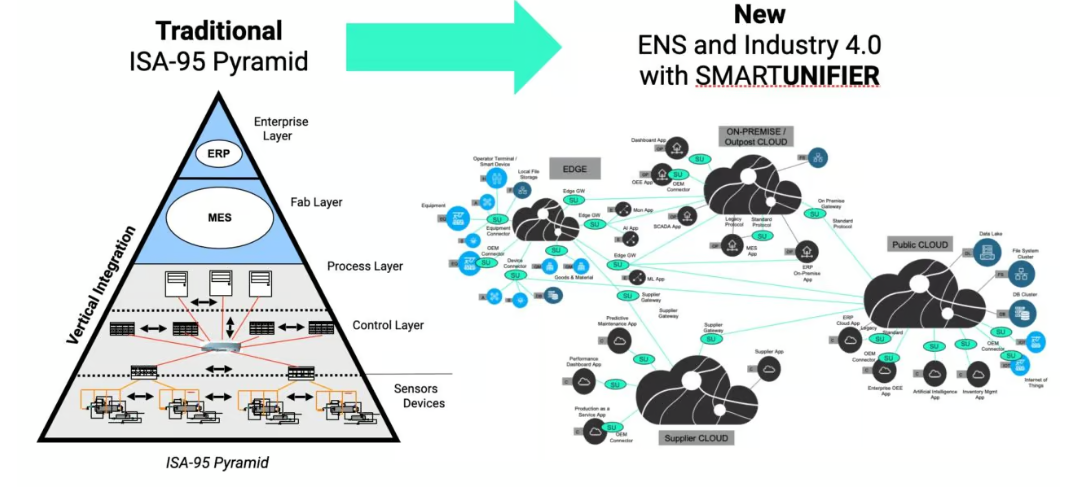

In its simplest form, SMARTUNIFIER can be deployed as an OT-IT Gateway, providing a structured and reusable interface between shop floor equipment and upper-level applications that can interpret and respond to the equipment data. SMARTUNIFIER provides an easy way to manage the connectivity, the protocol conversion, and the establishment of a semantic model. This functionality can readily achieve the vertical integration envisaged by the ISA-95 pyramid. The combination of connectivity, protocol conversion, information modeling, and mapping enables us to attain syntactic and semantic interoperability between the OT and the IT components.

However, there is far more to gain from exploiting the functionality to also establish horizontal integration and extend the syntactic and semantic interoperability throughout the collection of heterogeneous systems and components within an enterprise. Thus we can move from a traditional to a new paradigm, establishing an Enterprise Nervous System where inferences and responses are based on a system-wide perspective.

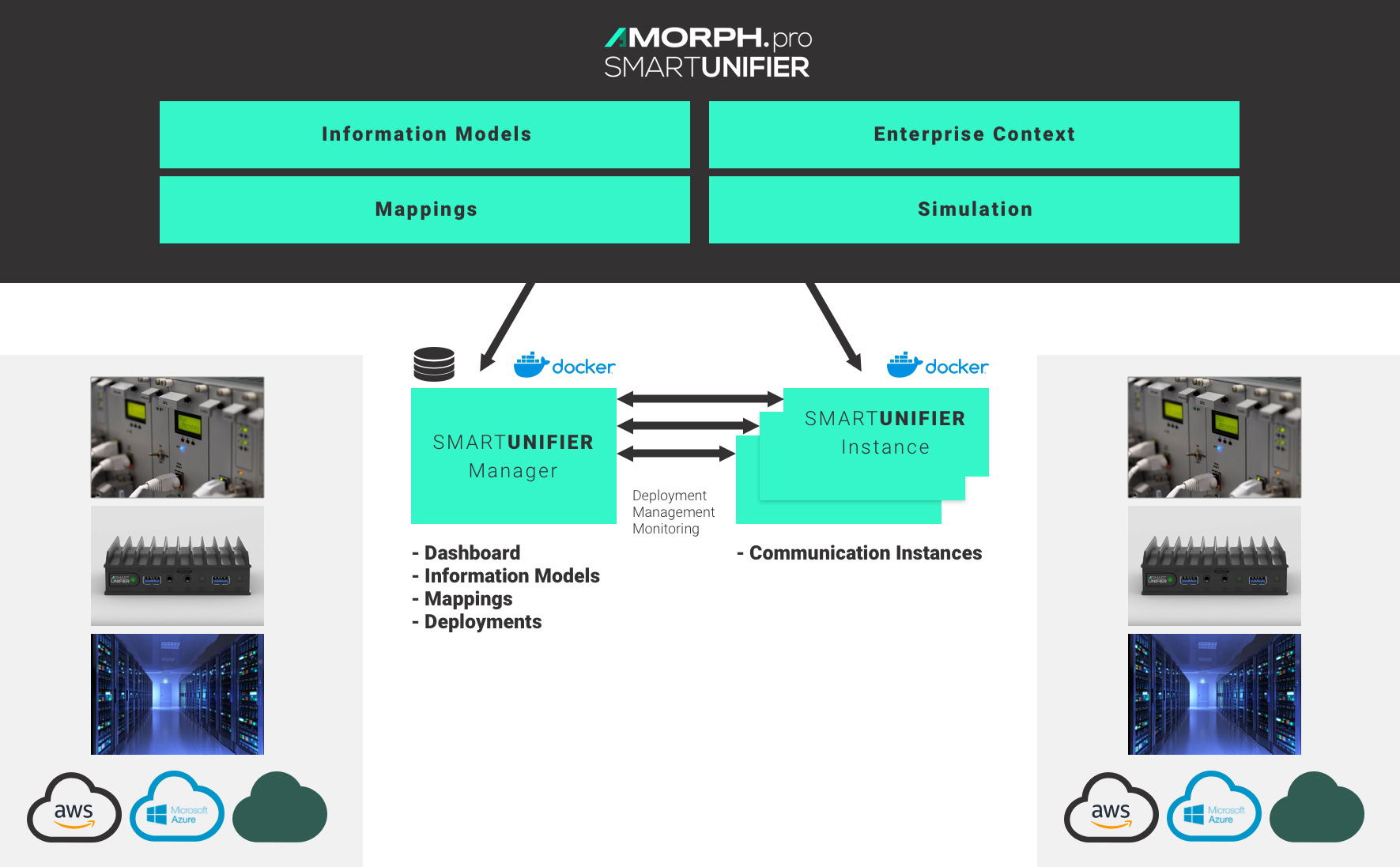

This move to an advanced Industry 4.0 ENS can be achieved because SMARTUNIFIER is based on a fully decentralized system architecture (Swarm) using Container Technologies for virtually unlimited scalability. The diagram below illustrates the architecture.

Real-time monitoring

With SMARTUNIFIER multiple decentralized Communication Instances can be deployed anywhere and centrally managed by the SMARTUNIFIER manager, including real-time monitoring and logging of deployed Communication Instances.

Deployments of Communication Instances can be on-premise (e.g., Industrial PCs, Edge Devices), in data centers, in the cloud, and hybrid deployments are also supported, enabling vertical and horizontal integration throughout an enterprise. More information on the integration components can be found at https://amorph.pro/lowercosts-for-it-integration-with-smartunifier/.

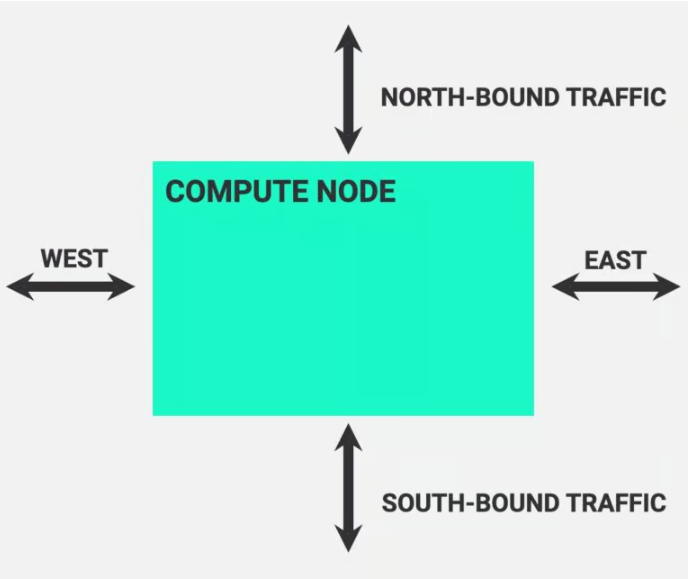

Within this context, each instance of SMARTUNIFIER provides protocol conversion and semantic alignment for all of its connected components in a Swarm topology. There is no requirement for a centralized platform to establish and manage all the connections. Each instance is an independent compute node that enables communication in all directions.

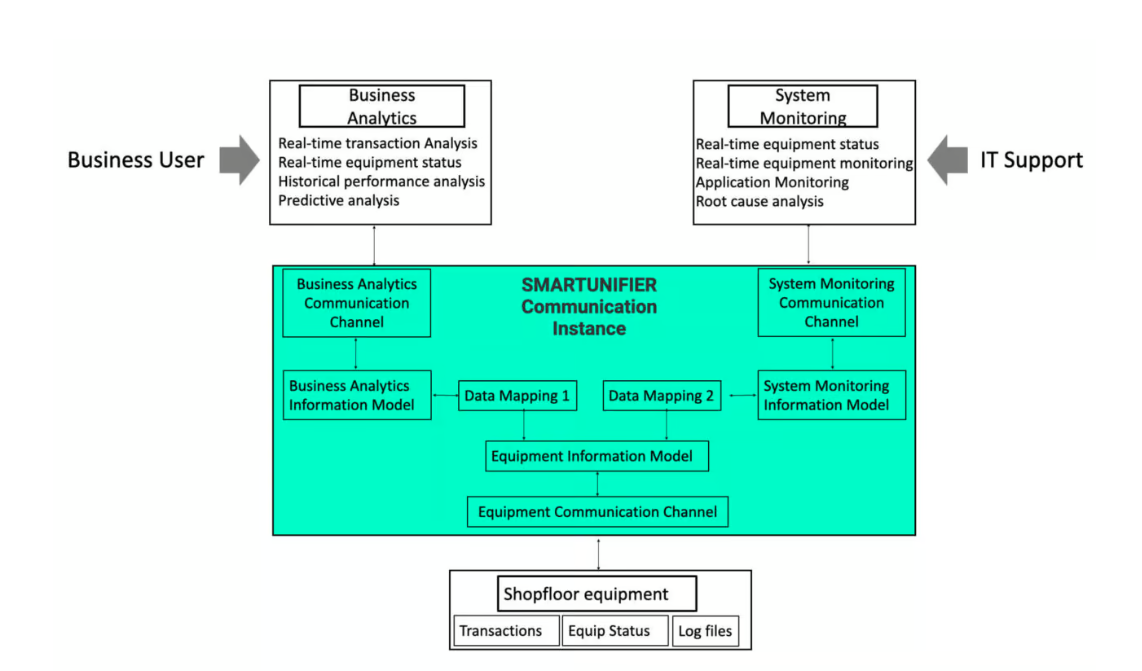

How this is achieved is illustrated in more detail by giving a common example of integrating shopfloor equipment with two northbound IT systems (Business Analytics, System Monitoring):

Use case: Interoperability between all the connected systems and equipment

In this example, the business user and IT support have insight into the equipment data from their own perspective. The Communication Channels establish the connection for each participant and handle their specific protocol conversions to achieve syntactic interoperability. The Information Models of each participant represent their view of the shared data, and the Mapping does the translations to achieve semantic interoperability. The manufacturing enterprise can extend this model with additional nodes connecting other systems such as Quality Control and Maintenance Management systems to share the Business Analytics and System Monitoring systems‘ data. SMARTUNIFIER facilitates the interoperability between all the connected systems and all the connected equipment.

The SMARTUNIFIER Manager provides central management of all the decentralized instances in a federated system, built in increments, to ultimately establish an Enterprise Nervous System.

Specific capabilities that differentiate SMARTUNIFIER as an integration platform include:

- Slim, lightweight, and platform-independent system

- Use of most modern technologies (e.g., Docker, AWS, Scala, Angular, …)

- Very high communication performance due to integrated compiler

- 100% seamless operation at the Edge, On-Premise, within the cloud as well as in hybrid environments

- Operation as a distributed application, or as Software as a Service (SaaS), or as Platform as a Service (PaaS)

- Parallel communication with legacy and new systems enables easy migration to modern communication protocols and standards

- An easy way for users to independently create information models and data unification maps.

SMARTUNIFIER paves the way to Industry 4.0!

If you would like to learn more about SMARTUNIFIER please reach out to us at info@amorph.pro.